Semiconductor

Back-end Inspection

-

Integrated Measurement System

半导体后工序外观检查

-

以 Micro Vision Technology 完美检查更加细微复杂的半导体封装工艺。

全球半导体制造商选择的INTEKPLUS优秀的视觉技术在半导体后工艺外观检查工艺中提供最佳的检查解决方案。

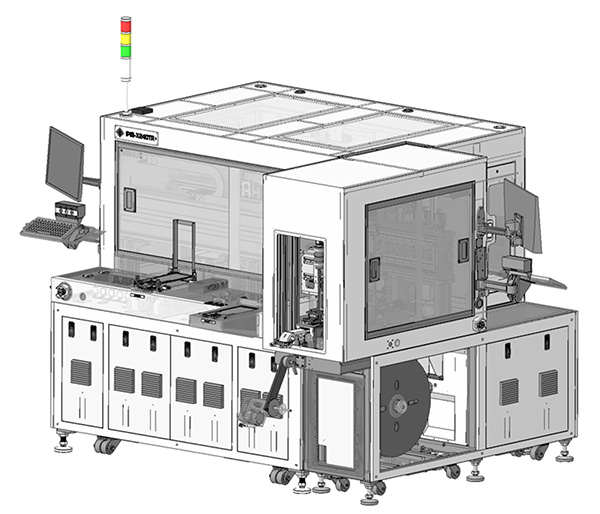

Semiconductor Package Inspection System

-

iPIS-HX Series

-

HIGH DETECTABILITY

HEXA PLATFORM -

Premium Solution of Supporting 6

Sides Inspection (Top/Bottom

2D/3D, 4 Side)High Detectability for Advanced

Package Inspection (SiP, CIS ···)Supports Advanced Inspection

Options: Real Total Height (Top 3D),

Top Side Dent, Side LFF Stitching,

Multi Picker and Deep Learning

Related Model : 140HX, 240HX,340HX -

HIGH DETECTABILITY

-

iPIS-XTR Series

-

EXTENDABILITY

TR PLATFORM -

All-in-one Inspection Solution

with 3 Rail for 6 Side + Tape & ReelCost-effective Upgrades which

enable to extend Equipment

LifecycleMaximized Extension Capability

Selective Inspection Available for

Customer Inspection Needs

(Advanced Package, Side

Inspection)

Related Model : X140TR, X240TR,X340TR -

EXTENDABILITY

-

iPIS-IN Series

-

IN-TRAY PLATFORM

INSTANT INSPECTION -

World Best Productivity Supporting

In-tray Handling method with 5 Rail

Based PlatformMinimize the Handing Damage with

Tray Flipping TechnologyStable Handing with Precise

Stitching for Large PackagesOption: HX Platform, Tape & Reel

Related Model : 380, 560, 580 -

IN-TRAY PLATFORM

- iPIS-HX Series

- 融合超高分辨率视觉解决方案与精密高速 Pick & Place 操作技术,带来最高生产率与高检出力

-

Inspection Stage2D Vision

Top / Bottom / 4 Sides

3D VisionTop / Bottom

-

General SpecificationInspection PKG

TSOP/ LDP/ QFP/ BGA/

BOC/ QFN/ usD CARD etc.UPHMax 80K

Package Size2x2mm ~ 120x120mm

-

ExtensionHexa(HX)

-

Related Model

iPIS-140HX

iPIS-240HX

iPIS-340HX

HEXA PLATFORM

140HX, 240HX, 340HX

Premium Solution of Supporting 6 Sides Inspection

(Top/Bottom 2D/3D, 4 Side)

High Detectability for Advanced Package Inspection

(CIS,SiP, Heterogeneous Integration)

Supports Advanced Inspection Options :

Real Total Height (Top 3D), Top Side Dent,

Side LFF Stitching , Multi Picker and Deep Learning

-

Pick & Place

Handling

Method -

UPH

Max 80K -

Top 2/3D

Bottom 2/3D,

4 Side -

Advanced

Package -

Direct View

Mechanism -

LFF Stitching

120x120

-

Real Total

Height -

Deep

Learning -

Multi

Picker

-

- Handling Method

- Pick & Place

-

- UPH

- MAX 70K

-

- Inspection

- Top/Bottom

2D/3D

-

- Package

-

Advanced

Package

-

- LFF

Stitching - 85x85

- LFF

-

- LTSM

- Long-term Stability Monitoring

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Extension 3

- Direct View Mechanism

-

- Feature 1

-

Top 3D

(Real Total Height)

-

- Feature 2

- Deep Learning

-

- Handling Method

- Pick & Place

-

- UPH

- MAX 60K

-

- Inspection

- Top/Bottom

2D/3D

-

- Package

-

Advanced

Package

-

- LFF

Stitching - 80x80

- LFF

-

- LTSM

- Long-term Stability Monitoring

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Extension 3

- Direct View Mechanism

-

- Feature 1

-

Top 3D

(Real Total Height)

-

- Feature 2

- Deep Learning

- iPIS-XTR Series

-

In-Line TR AVI是整合Machine Vision Inspection System和Conventional Tape&Reel Handler的Tape&Reel一体性检测解决方案,

可追加Auto Reel Changer实现Post Reel Process的完全自动化。

-

Inspection Stage2D Vision

Top / Bottom / 4 Sides

3D VisionTop / Bottom

-

General SpecificationInspection PKG

TSOP/ LDP/ QFP/ BGA/

BOC/ QFN/ usD CARD etc.UPHMax 70K

Package Size -

Extension

Auto Reel Changer(ARC)

-

Related Model

iPIS-X140TR

iPIS-X240TR

iPIS-X340TR

TR PLATFORM

X140TR, X240TR, X340TR

All-in-one Inspection Solution with 3Rail for 6 Side + Tape & Reel

Cost-effective Upgrades which enable to extend Equipment Lifecycle

Maximized Extension Capability

Selective Inspection Available for Customer Inspection

Needs(Advanced Package, Side Inspection)

-

Pick & Place

Handling

Method -

UPH

Max 70K -

Bottom

2/3D,

Top 2D -

Tape &

Reel

Extension -

Direct View

Mechanism -

Vision

Extension

Available

-

Multi Picker

-

Deep

Learning -

Auto Reel

Changer

Auto Reel Changer enables to automate Reel Taping,

Barcode Label Attach and Protection Bander attaching,

which was inevitable by the operator.

-

- Reel Taping

-

- Barcode Label Attach

-

- Label Printer

-

- Dual Reel Changer

-

- Protection Bander

-

- Finished Reel Stacker

- iPIS-IN Series

-

In-Tray平台是指封装半导体在Tray盘内的情况下直接进行检测。

INTEKPLUS的Tray Flipping技术可实现对产品毫无损伤并且快速准确进行检测。

-

Inspection Stage2D Vision

Top / Bottom / 4 Sides

Top / Bottom -

General SpecificationInspection PKG

TSOP/ LDP/ QFP/ BGA/

BOC/ QFN/ usD CARD etc.UPHMax 100K

Package Size3×3mm ~ 120×120mm

-

Extension

Hexa(HX) / Tape & Reel (TR)

Auto Reel Changer(ARC)

-

Related Model

iPIS-380

iPIS-560

iPIS-580

INSTANT INSPECTION

380, 560, 580

World Best Productivity Supporting In-tray Handling method with 5 Rail Based Platform

Minimize the Handling Damage with Tray Flipping Technology

Stable Handling with Precise Stitching for Large Packages

Option: HX Platform, TR

-

In-tray

Handling

Method -

UPH

Max 100K -

Bottom

2/3D,

Top 2/3D -

2D/3D LFF

Stitching -

Tray

Flipping

Technology -

Auto

Sorting

System

-

HX

Platfom -

Tape &

Reel -

Side LFF

Stitching -

Deep

Learning

-

- Handling Method

- In-tray

-

- UPH

- MAX 85K

-

- Inspection

- Top/Bottom

2D/3D

-

- LFF

-

2D/3D

Stitching

-

- Damage

- Damage

Free

-

- Sorting

- Auto System

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Feature 1

- Deep Learning

-

- Feature 2

- Tape & Reel

-

- Handling Method

- In-tray

-

- UPH

- MAX 100K

-

- Inspection

- Top/Bottom

2D/3D

-

- LFF

-

2D/3D

Stitching

-

- Damage

- Damage

Free

-

- Sorting

- Auto System

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Feature 1

- Deep Learning

-

- Feature 2

- Tape & Reel

- Module/SSD AVI

-

INTEKPLUS的Module FVI Inspection Platform是用于检测Memory的外观缺陷

通过光三角法的实时3D检测法,可对应多种尺寸的产品检测

-

Memory ModuleSSD AVI

-

Inspection StageiMAS-2000

DIMM, SODIMM, FBDIMM

iSSD-Q1000D2.5” SATA, mSATA, RAID LIF, Gumstick1, Gumstick2

-

General Specification

Top/Bottom 2D&3D

Top/Bottom 2D&3D

Side 2D -

Extension

2,000 EA

(@SODIMM)6,000 EA

(@ 2.5” CASE) -

Model

- iMAS-2000

- iSSD-Q1000D

-

- UPH

- Max.2000

-

- In-out

- Direct Tray In-out

-

- Review

- Reject Review Station

-

- Sorting

- Auto Sorting

-

- Light System

- 3Band Light System

-

- Job Teaching

- Fast Job Teaching

-

- UPH

- Max.6000

-

- Inspection

- 5Para Single

Head Inspection

-

- Review

- Reject Review

Station

-

- In-out

- Direct Tray

In-out

-

- Auto Conversion

- Inspection 专用 JIG

Auto Conversion

-

- Sorting Picker

- Sorting Picker

-

- Light

- 3Band Light System

-

- Job Teaching

- Fast Job Teaching

-

- Sorting

- Auto Sorting